Monitoring of the production process and machine downtime

Quality Management Software Q-LanYs

Nowadays, it is necessary not only to constantly improve and optimize the quality of manufactured products, but also to place great emphasis on increasing labor productivity and reducing the cost of production processes. For this purpose, a "machine downtime and production process monitoring system" was developed to identify weaknesses in labor productivity and activities affecting the cost and productivity level of production processes. This means that you are able to detect weaknesses in the areas of material logistics, work organization, technical condition of machines and also in the area of quality of manufactured products.

Q-LanYs Pack 2024 Monitoring the downtime of machines and production processes

To ensure the availability of our system even for small companies, variant solutions are available from the simplest system configuration to a sophisticated system enabling monitoring of machines, monitoring the number of cycles, number of manufactured products, production reports, SPC (statistical process control), monitoring the proportions of planned events as maintenance, reconstruction of machines and the possibility of online monitoring of products quality parameters or technological parameters.

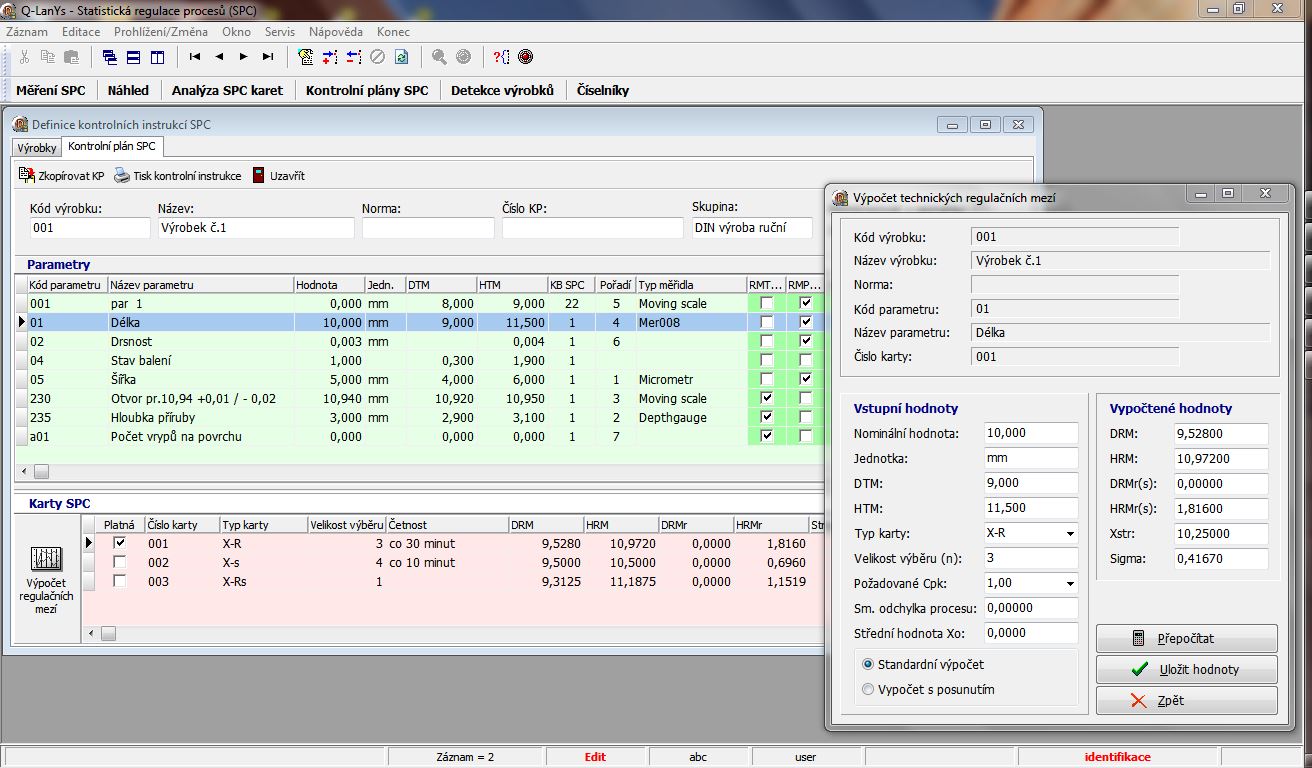

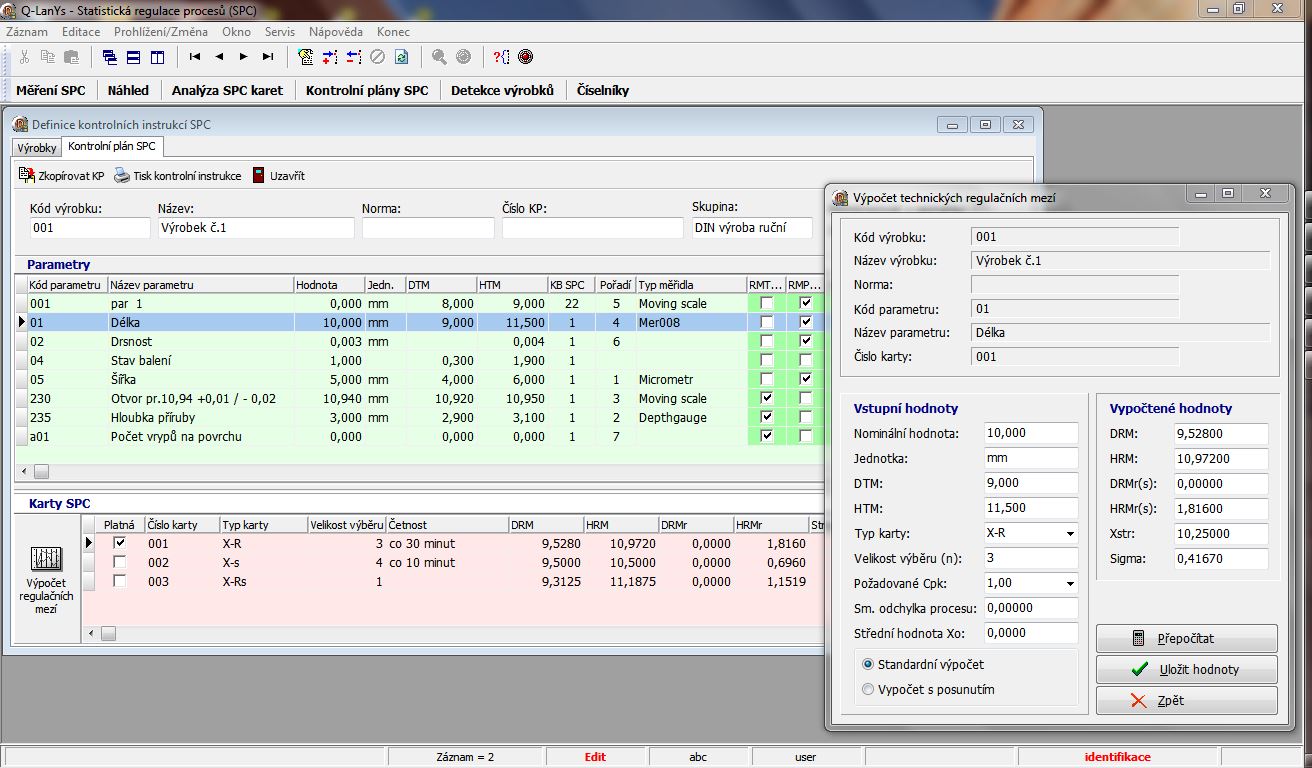

If necessary, we are also able to provide data-free transmission of monitored pulses. Furthermore, this product allows the collection of data on ongoing production or product directly from the production process and also perform statistical control of product parameters (SPC) directly at the workplace or operation.

If necessary, we are also able to provide data-free transmission of monitored pulses. Furthermore, this product allows the collection of data on ongoing production or product directly from the production process and also perform statistical control of product parameters (SPC) directly at the workplace or operation.

According to the complexity of the configuration of the monitoring system, it can be divided into configuration:

- Basic - The simplest configuration to monitor the "off / on and does not produce / on and produces / event" state of the machine. The event means, for example, machine maintenance, conversion to another product, etc. Furthermore, the frequency of production cycles, the number of products produced, etc. Based on the obtained data, it is possible to analyze the monitored process using graphs and calculated statistics.

- Standard - In addition to the BASIC configuration, an operator panel is located at the workplace, which can be used to make production reports, identify downtime by entering downtime codes, and further monitor events, including their time requirements.

- Professional - A comprehensive monitoring system with the possibility of monitoring downtime, identifying the causes of downtime, monitoring events (machine maintenance, rebuilding, etc.), production reporting, SPC and online monitoring of quality and technological parameters.

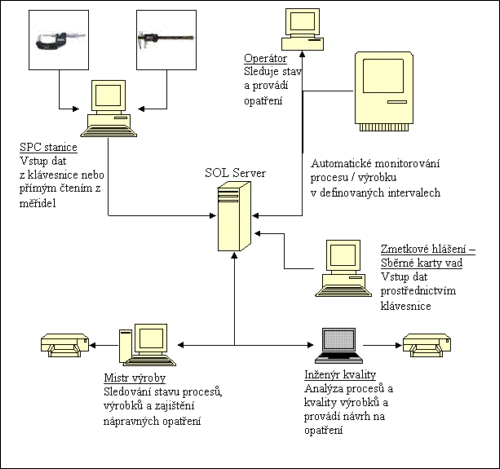

Scheme of monitoring systems

Screens and forms used

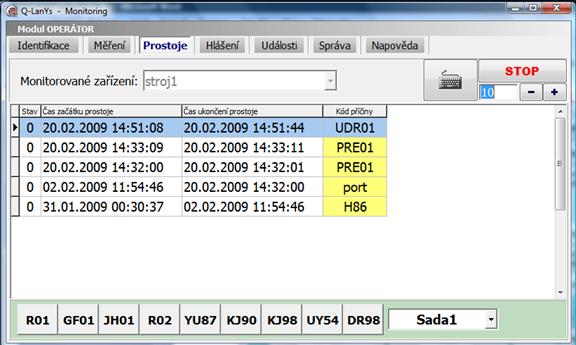

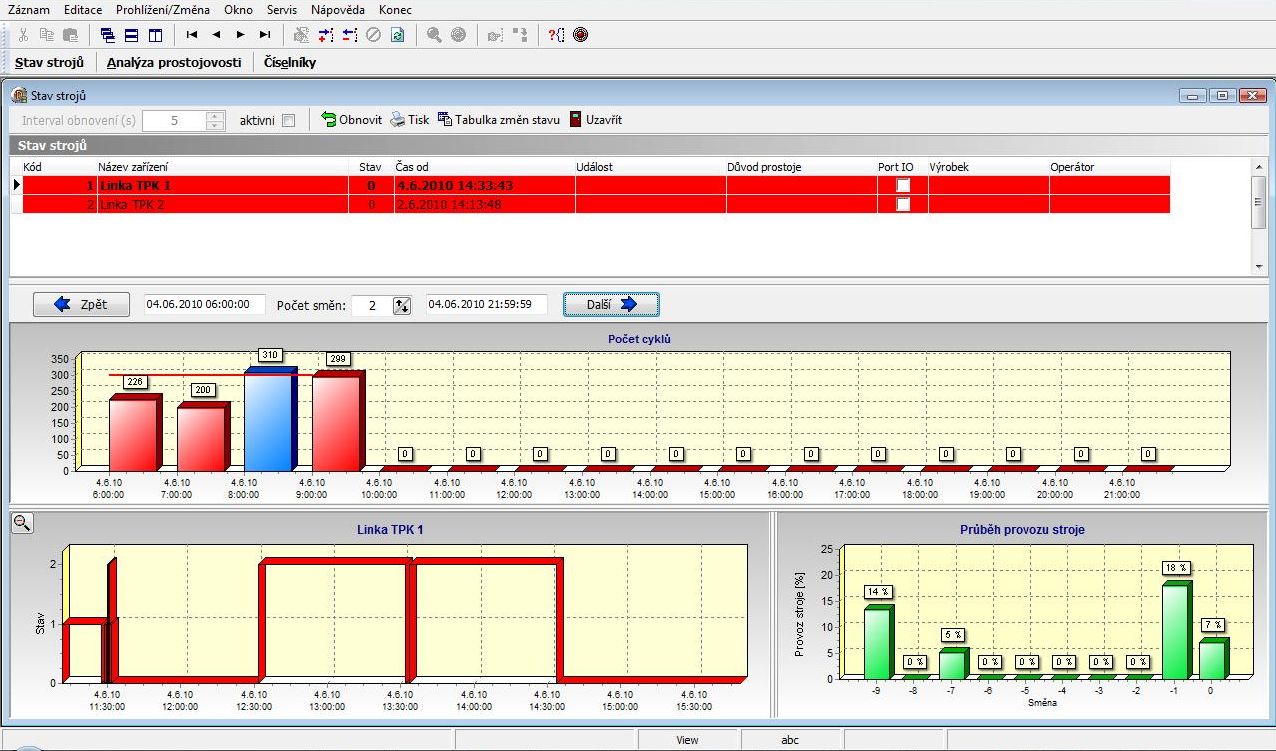

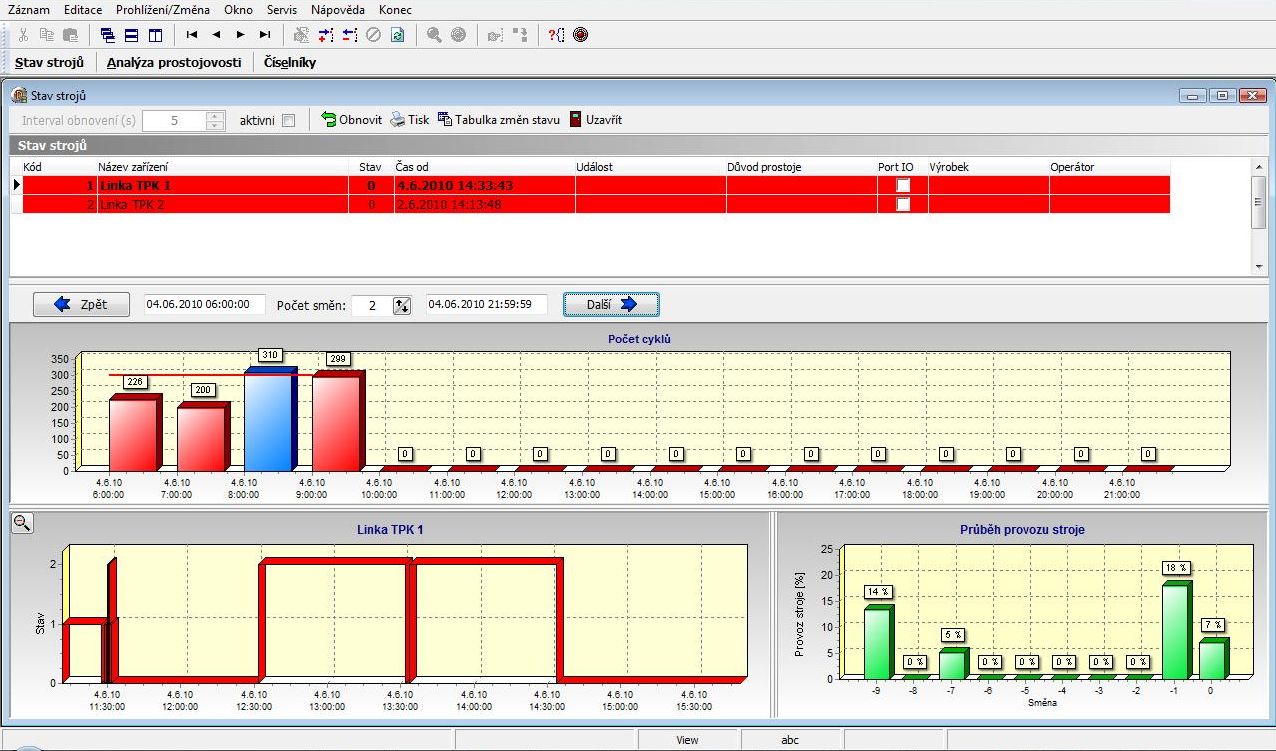

Monitoring the machine status progress

Graphic monitoring of the status of monitored machines (production lines) based on data recorded by the "Monitor" software.

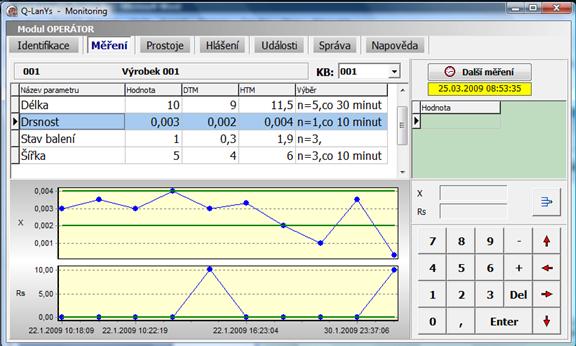

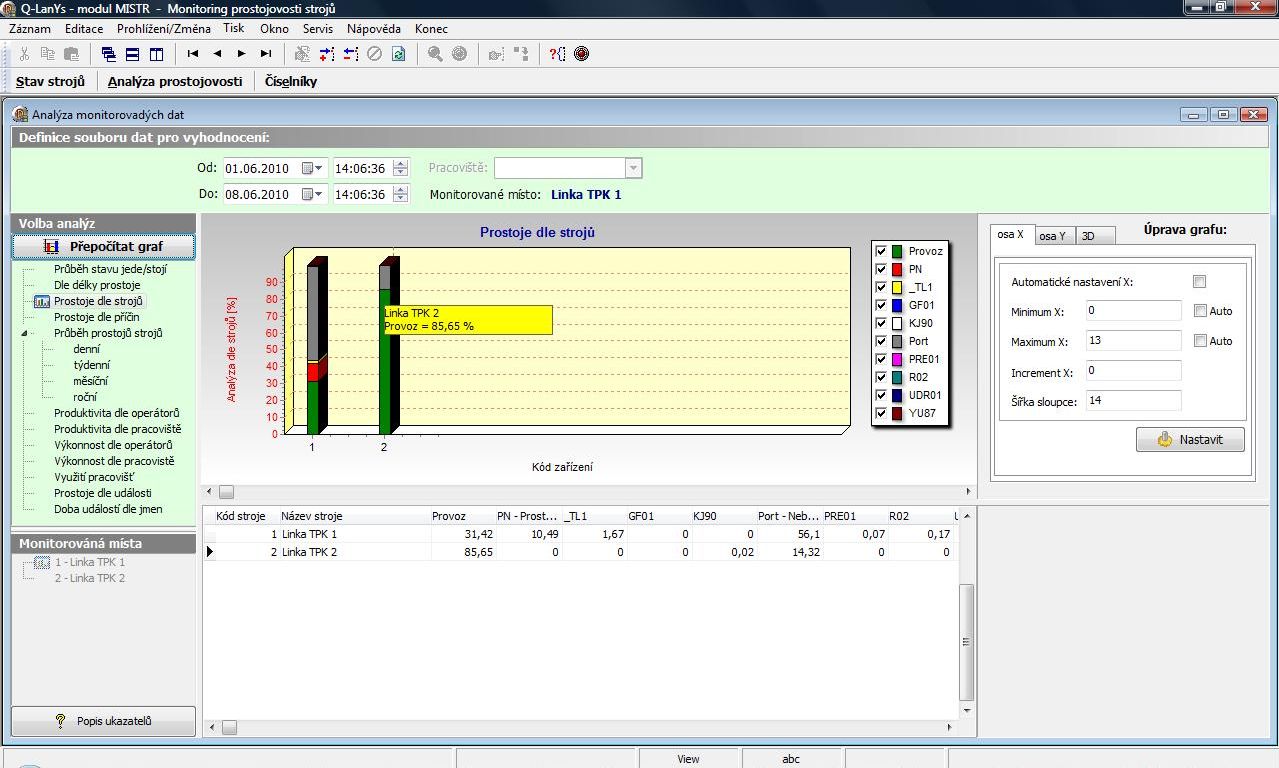

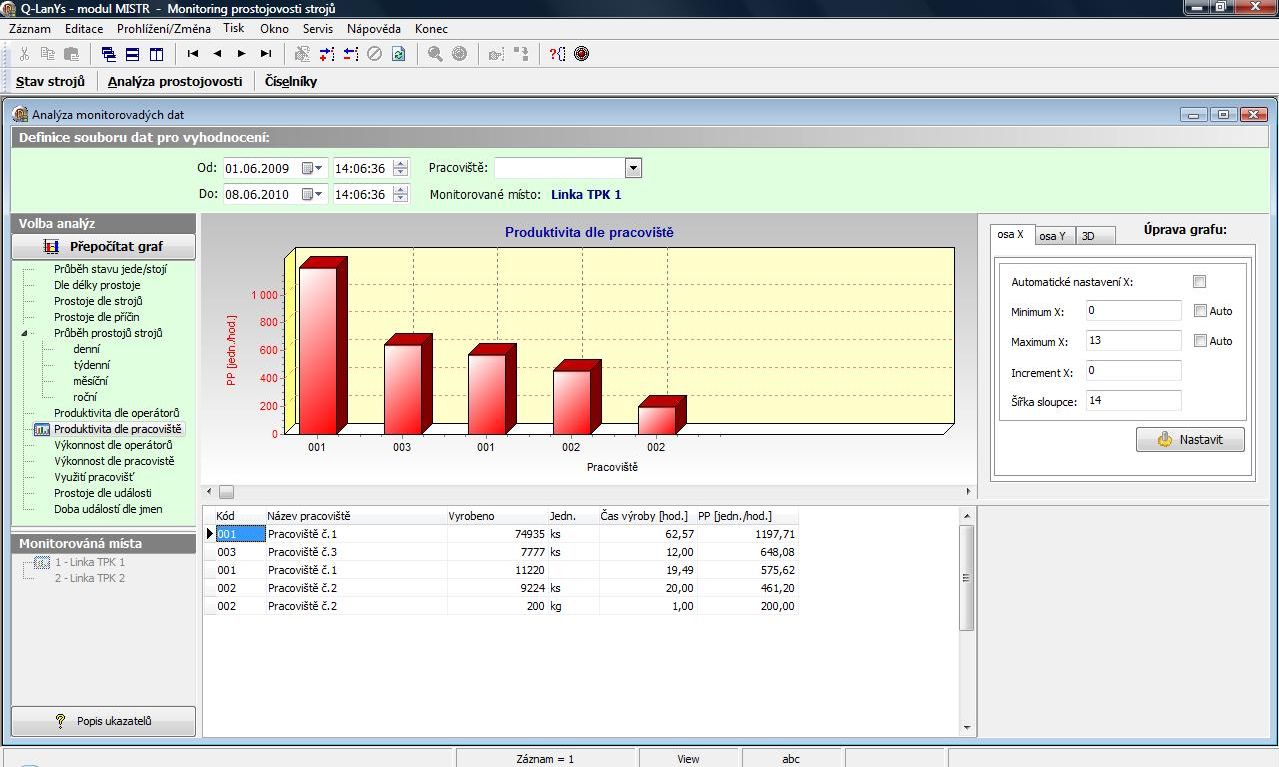

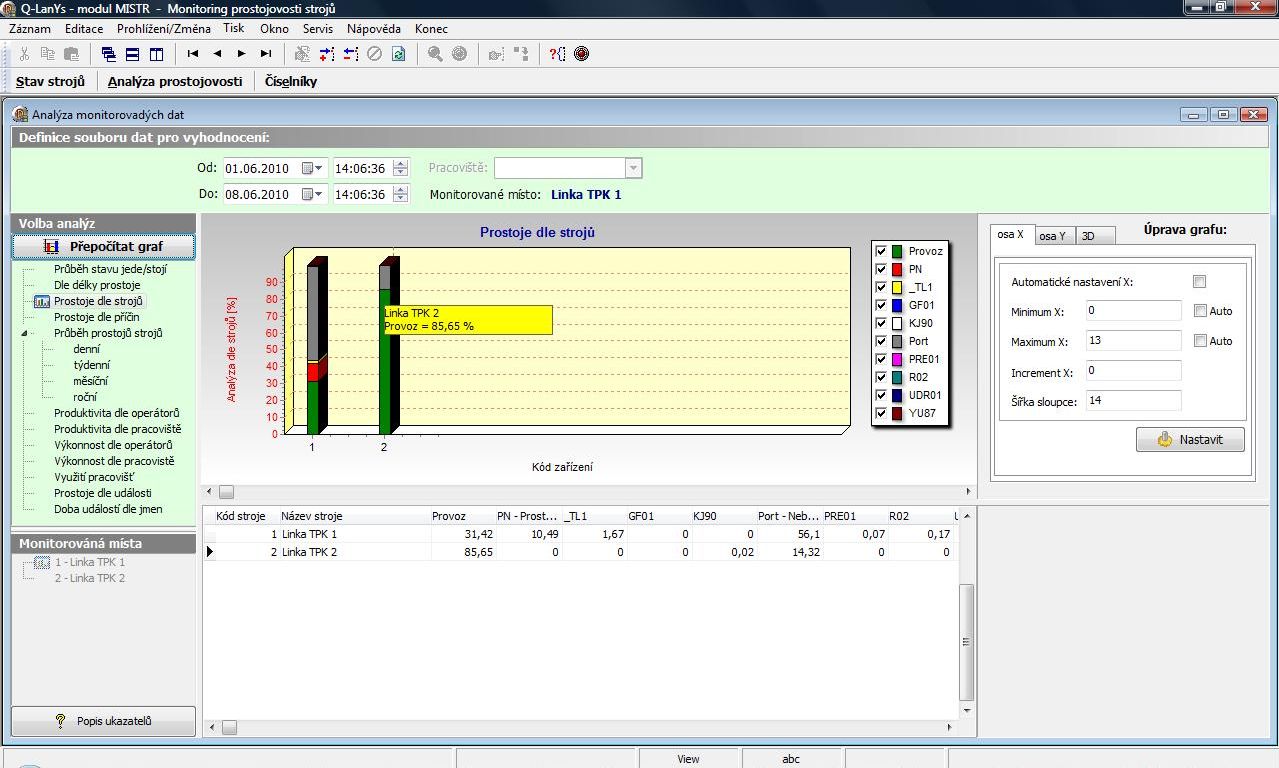

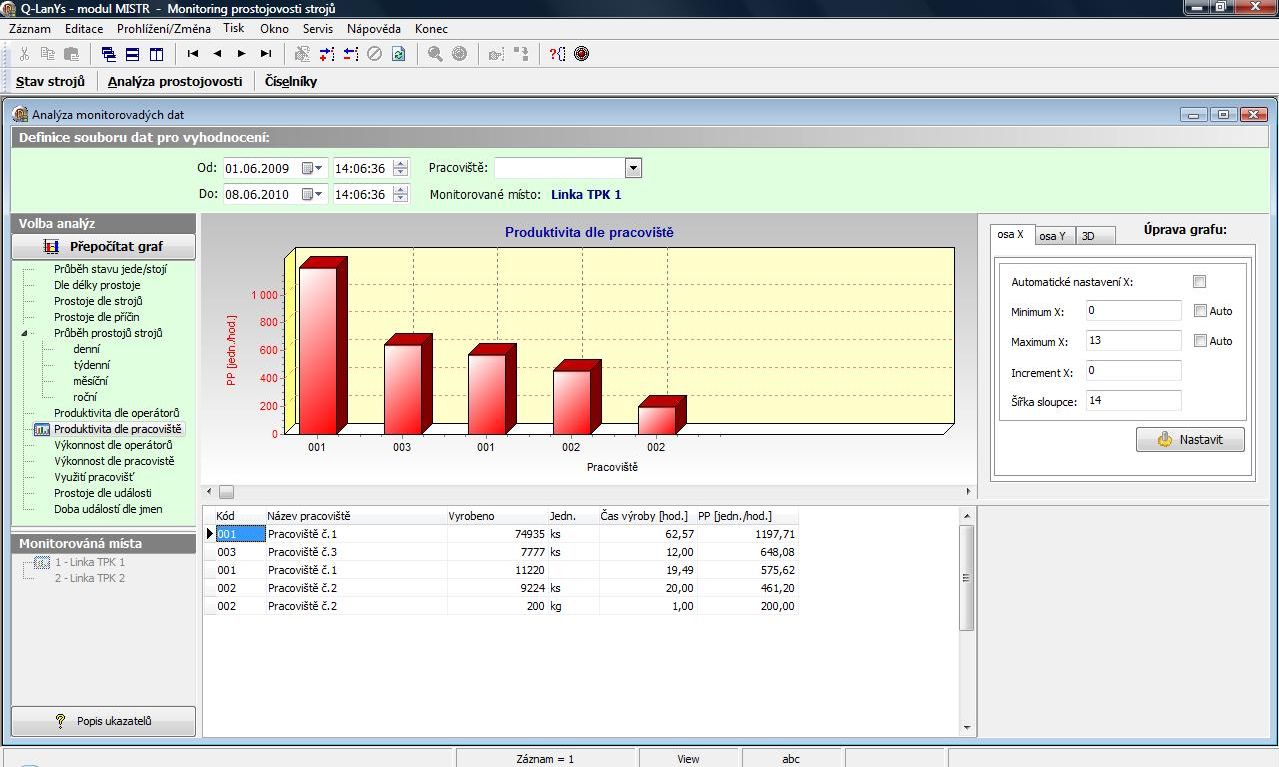

Analysis of monitored data

Analysis of recorded data to determine the actual state and trends of downtime and productivity of machines according to various aspects (events, workplaces, workers, causes of downtime, etc.)

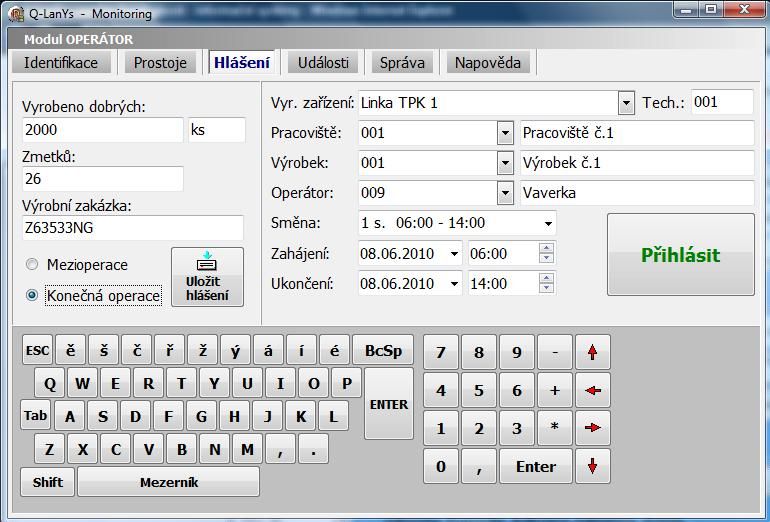

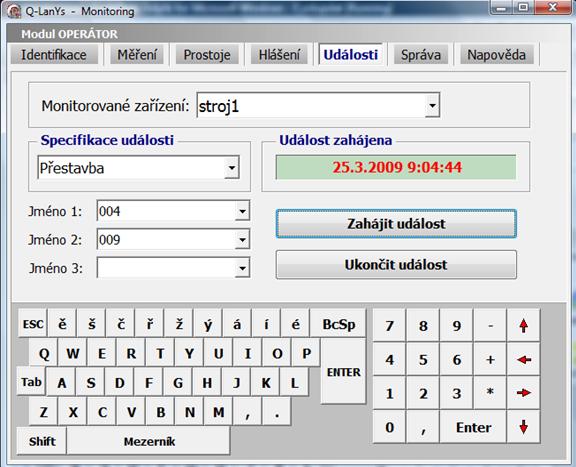

Operator panel

It is an application designed specifically for operators who can record important information such as:

- causes of downtime

- start and end of events (maintenance, conversions, etc.)

- perform SPC directly at the workplace

- record data on produced production and scrap (production report)

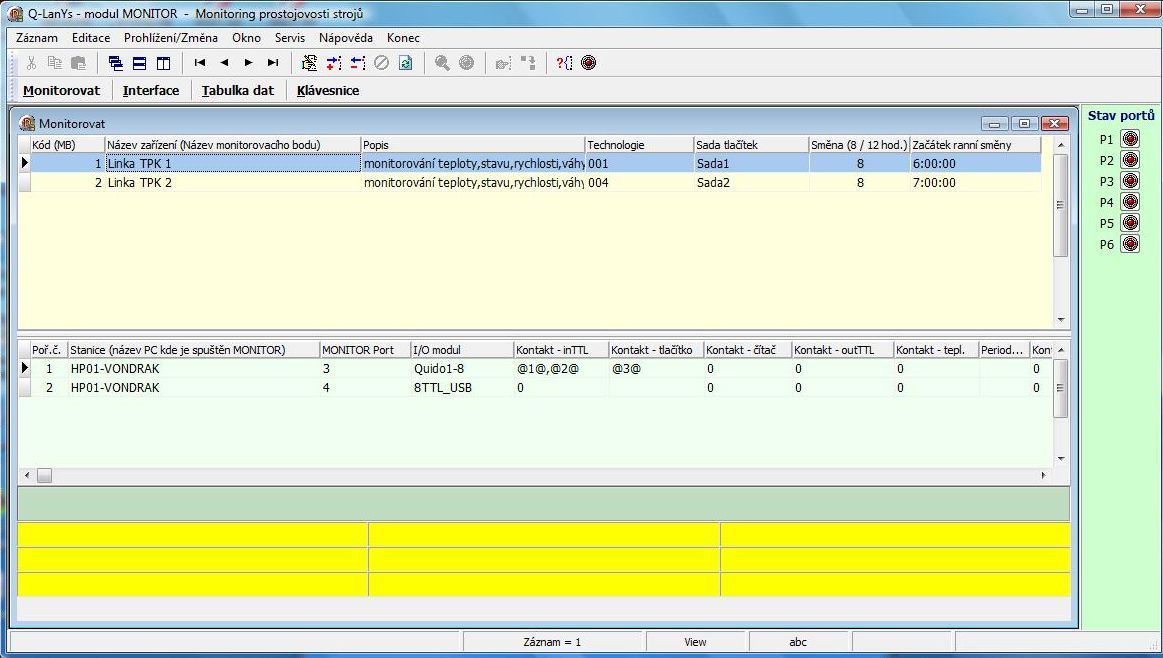

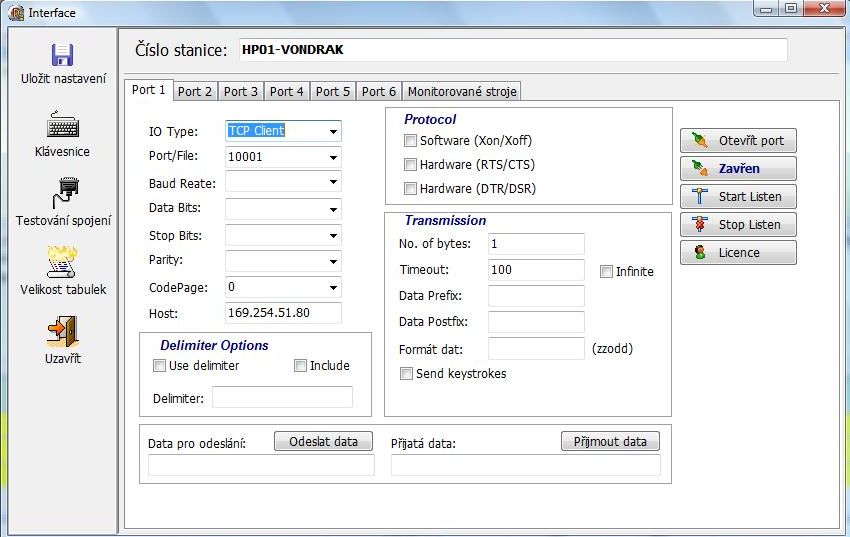

Monitoring system configuration settings

The "Monitor" software provides settings for the monitoring system, its own communication with the device indicating downtime of the monitored machine (production line) and recording of their status on the SQL server.

Are you interested in our services? Are you interested in further information about our products and services? Do not hesitate to contact us.

Non-binding request